TECHNOLOGICAL PROCESS:

Nitrided screw processing:

Cutting → Heat treatment (quenching and tempering) → Rough machining→Semifinishing → Finish machining → Rough gr inding → Heat trea tment (Ni tridation) → Accurate grinding → Inspection → Acceptance check

Alloy screw processing:

Cutting → Heat trea tment (quenching and temper ing) → Rough machining → Semifinishing → Fini shmachining → Spraying of alloy on the screw edges → Rough grinding → Heat treatment (Ni tridation) → Accurate grinding → Inspection → Acceptance check

Nitrided barrel processing:

Cutting → Rough machining of the barrel' s inner surface → Heat treatment (quenching and tempering) → Finish machining → Rough grinding → Heat treatment (nitridation) → Accurate grinding → Inspection → Acceptance check

Nitrided barrel processing:

Cutting → Rough machining of the barrel' s inner surface → Casting alloy on the barrel' s inner surface → Finish machining → Accurate gr inding → Inspection → Acceptance check

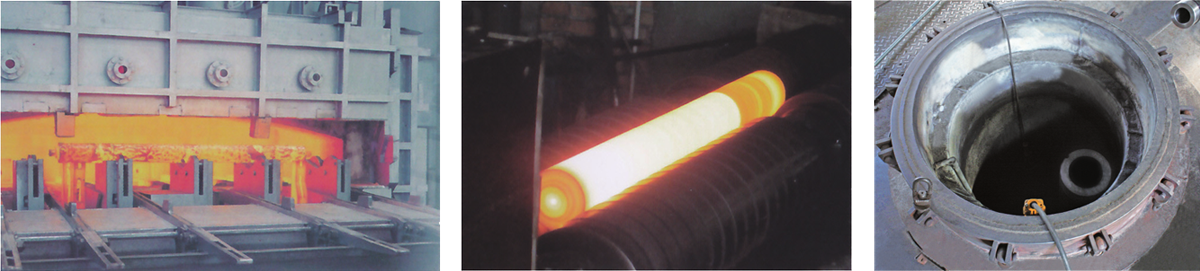

Heat trea tment:

1. Quenching and tempering:

It means to heat, quench and temper the raw material and to keep it warm so that the material becomes strong in toughness and hardness. It can polong the service life of screw barrels and reduce the deformation of them.

Hardness after quenching and tempering: HB≥260

2. Setting treatment:

It means to heat the screws after rough machining. The temperature should be higher than that in ni trogen treatment. The screws after setting treatment will not deform or bend in the following ni trogen treatment.

3. Ni trogen treatment:

The hardness of our screw barrels after nitridation is more than HV900 , so that they have excellent wear resistance, fatigue resistance, corrosion resistance and high temperature resistance.

Hardness after nitridation:HV≥900

Nitriding depth:0. 5-0. 6mm